ICE SKATE SHARPENING SERVICE

We take sharpening your skates VERY seriously.

We’re careful, pay attention to detail, and guarantee satisfaction!

with a combined total of 79 years sharpening experience and a blademaster triple head machine, the staff at churchill rink have the knowledge, equipment and ability to sharpen your skates properly and to your liking!

Not too familiar with skate sharpening? learn more about it by reading the information at the bottom of this page.

$7.00 per pair while you wait or drop off and pick-up later.

PLEASE DON'T RUSH IN 30 SECONDS BEFORE YOUR SKATE AND hope we'll have time TO DO THEM - WE ARE OFTEN BUSY DOING OTHER THINGS SO LAST MINUTE ISN'T Always a GOOD IDEA!

Sharpening is available whenever the rink is open and staffed but based on what's happening at the rink, you may need to be patient or leave and pick up later. The rink is often staffed by just one person and if they're busy doing something time sensitive like driving the Zamboni, they won't be able to do your skates immediately.

During the winter season, the rink is typically open for skate sharpening on the following schedule. (NOTE-These are NOT our public skating hours.)

Monday, Tuesday, Wednesday, Thursday - Noon to 10pm

Friday - 10:30am-10pm

Saturday - 7:30am-10pm

Sunday - 8:30am - 7pm

If you ever have an issue with how we sharpened your skates, or you like the job we did, please let us know! We want you to be happy with the job we do.

The process of sharpening – how it works

If you’ve ever looked closely at the bottom of your skates, you may have noticed each blade has not one edge like a knife but two edges with a hollowed-out area in between. This shape is created by sharpening the blade with a precision grinding wheel with a rounded surface like the one we use here at Churchill Rink. Skates are clamped into a holder which when done right is then accurately aligned with the finishing wheel. The blade is gently passed along the spinning finishing wheel until the edges are sharp and the bottom is fully hollowed out.

Prior to the finishing wheel, it’s often a good idea for us to use the cross-grind wheel to prep the blade for finishing. Unlike the finishing wheel, the cross-grind wheel runs perpendicular to the skate blade and is designed to flatten the blade rather than sharpen it. It’s used to reset the blade to a blank state, ready to be re-finished. This step is not always necessary but is a great way to ensure the machine operator is starting fresh and removing any major defects such as a prior sharpening mistake or nicks. If you have your skates sharpened at the same place all the time, the operator will become familiar with you and know your skates were probably done correctly the last time. Operators who make mistakes tend to make the same mistakes over and over again and we see this every day!

Customizing your sharpening

There is one aspect of sharpening we can be customize for you here called “radius of hollow” or ROH. As mentioned earlier, sharpening your skates involves passing them over a spinning stone with a rounded surface. This surface can be modified to have a more curved surface or a flatter one. “Dressing” the wheel to the desired radius allows us to transfer a specific radius to your blades.

A larger radius means a flatter grinding wheel and a skate with less hollow. The normal range for hollow is 1/2” to 5/8” although larger or smaller hollows are occasionally preferred. Unless otherwise specified, we sharpen hockey skates and hybrid recreational skates at 1/2” ROH and Figure Skates at a 1” ROH.

GOALIE SKATES will be done as specified by the goalie as preference varies among them. In the old days, before the butterfly technique became the norm, goalies liked very flat skates so they could slide side to side without catching edges. These days, it's common for goalies to request a ½” or 5/8” radius which allows them better bite for pushing off while kneeling.

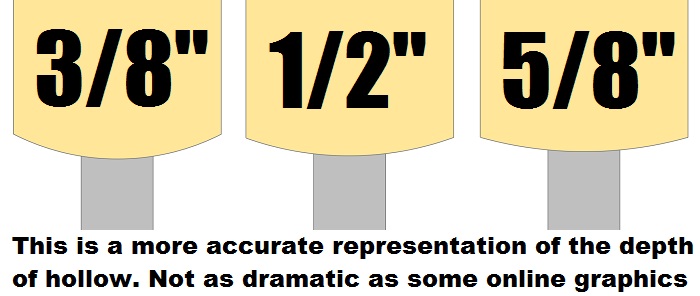

In the graphic below, you can see what the different ROH's look like.

Different hollows will affect how the skate feels and how it interacts with the ice. Deeper hollows will put more pressure on the edges of the blade and dig into the ice more. Shallow hollows will do the opposite distributing pressure more evenly across the width of the blades causing them to sit more on top of the ice.

How “radius of hollow” can affect your game

- Smaller radius of hollow ( ⅜”)

- Deeper cut on skates.

- Better suited to lighter players who dig in less to start with.

- More energy lost into ice.

- Extra effort required to skate.

- Lower top speed.

- Potential for “chatter” or “skipping” while stopping.

- More responsive turns and stops.

- Quicker, more explosive acceleration.

- Larger radius of hollow (⅝”)

- Flatter cut on skates.

- Better suited to heavier players who have no trouble gripping the ice.

- Less energy lost into ice.

- More efficient skating.

- Faster top speed.

- Turns and stops will be less quick or sharp.

- Acceleration is more limited.

Major Sharpening “mistakes” and how to spot them

By mistakes I mean things the operator did wrong during a sharpening. There are two common mistakes that happen frequently for which the only solution is to get your skates re-sharpened.

- Improper holder alignment:

- This happens when the operator doesn’t align the skate holder with the skate in it to the grinding wheel properly. It causes one edge to be higher than the other. (see 2nd graphic below)

- Skates will have plenty of bite when turning/stopping on the high side but will feel like they’re slipping out when your weight is on the low side.

- When looking down the length of the blade, you’d be able to see one edge is higher/lower than the other if this has happened on your skates. If you balance a coin or other flat object on the top of the blade, you may be able to notice if it exists on your skates. We have a special tool for checking this important aspect of a proper sharpening.

- Not fully sharpened:

- This is when your skates are cross-ground but then not completely hollowed back out. Skates will have very little bite in every direction, making it tough to push, turn, stop, or do much of anything. This is because the blade was flattened from the cross-grind wheel, but the sharpener didn’t pass it over the finishing wheel enough times for it to regain its edges.

- When looking at the bottom of the blade, you’ll see two thin lines running down the edges with a different texture (rough). (See picture below)

Minor sharpening “mistakes” to watch for

These problems won’t make it impossible to skate but are worth knowing about.

- Over-sharpening the tip & tail

- A hockey skate is designed to be relatively (but not entirely) flat in the middle two-thirds of the blade, and rockered at the ends for agility. Maintaining this profile requires a light touch.

- Too hard & too fast

- To give the blade a nice, smooth edge, your sharpener should be passing it over the wheel slowly but lightly. Going too fast (especially on the final few passes) can create burrs and rough spots along the edges.

Other common questions

- How often should I sharpen my skates?

- This is a personal choice. Some players sharpen frequently, such as every 2-3 hours of ice time, while others go for an entire season without sharpening. If you’re unsure of where to start, try getting them sharpened after 5 hours of ice time, and then adjust as you feel is necessary.

- It’s also worth noting that colder ice (especially the type found at Churchill Rink) is much harder, and will dull your skates very quickly. Also, hard ice requires sharper skates! If you’re playing with your buddies on the outdoor rink, it’s probably a good idea to get a sharpening done more frequently.

- Really, good, experienced skaters just plain know when it's time to get their skates sharpened. For instance...got a big game? Get-your-skates-sharpened!

- What should I be doing to maintain my skates in between sharpening?

- A hand stone is a great choice for maintaining your blades. Its job is to smooth out any burrs or nicks that can form on the sides of your blades. We sell these stones in our small shop.